This is a long story with a lot of backstory, but a lesson learned.

Backstory

In 2010, I came home from work to hear that my AC wasn’t working. Up until this point, I had never done anything with HVAC besides set my thermostat and change air filters. It was miserable. We’re accustomed to keeping things very cool all year round and this was the middle of the summer. I spent some time learning about different components and decided to replace the capacitor and condensor fan motor. This got things back up and running.

The AC was not long for this world, however. The next year, things got a little worse and the AC wasn’t keeping up well. I decided to get some solar screens (think screen material for when you open your window, but heavier gauge to block more light from entering). This helped things limp along; the screens reduced the temperature directly inside sun-facing windows by 30F.

As an example (and not affiliated in any way), the Solar Screen Outlet offers custom solar screens. I bought the materials at Menards, including the screen frames and made them myself.

By 2012, it was dead. We bought two portable air conditioners that were 1-Ton units and were able to make it through the next year.

We replaced our entire HVAC system in 2013. This was an overreaction driven by impropriety in the HVAC industry. We needed a new AC, we got a new furnace, an additional supply line in the master bedroom (needed), and return lines in each bedroom (also needed).

A month later, we had a storm and lightning struck our line set, splitting it and letting the refrigerant escape. The cost was basically the same as our homeowner’s insurance deductible, so we paid to get it replaced.

It was a miserable situation, but we made it work and we learned.

Present Day

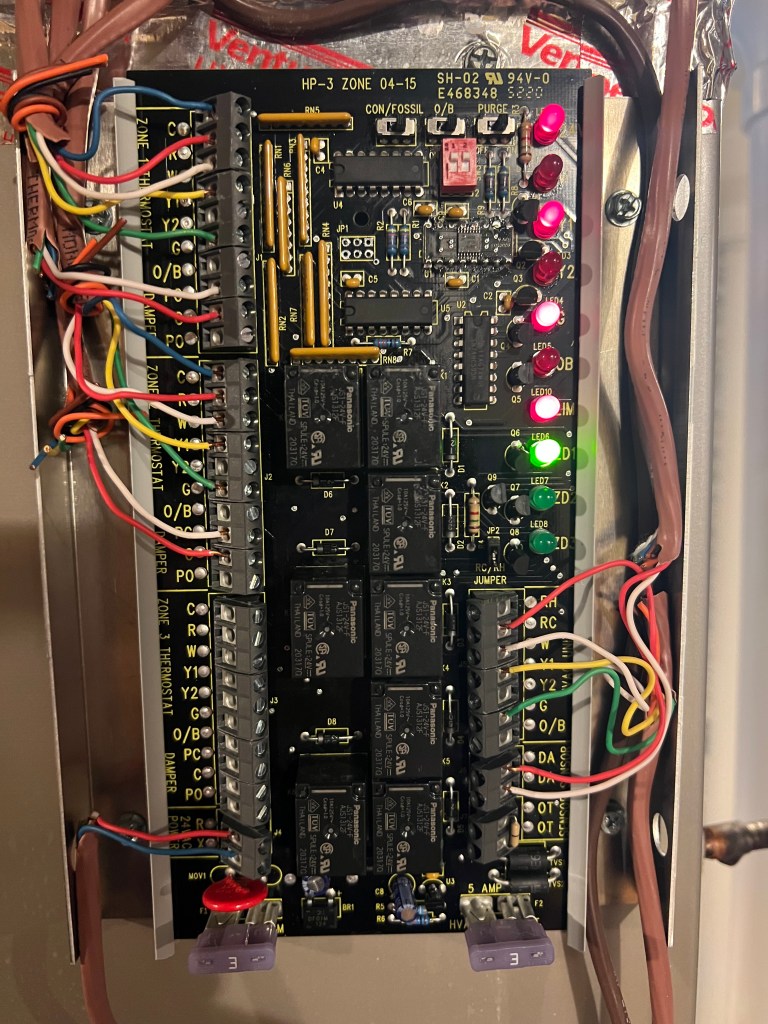

We had moved to a new house a couple of years later and we’ve now been in the house for many years. The HVAC system in the new house was actually the same as the system we had installed into the old house, but the new system was the Bryant Evolution brand and the old house had the Carrier Infinity brand (as with so many brands, they’re the same manufacturer). A couple of months ago, we started to notice that there were issues brewing. Upstairs started to remain warm and I leared that the zoing system we installed to better control our indoor climate was the culprit. The damper for the upstairs zone was stuck closed, so I had to search through the attic to find and force it open. I also started doing more maintenance tasks on the HVAC, but I had been doing those things for a while, like cleaning the coils and ensuring things were in good working order.

Not wanting to repeat the past, I dove into learning about HVAC; primarily refrigeration. I got the EPA 608 certification so I could handle refrigerants. I ordered some tools to test my system. However, it was too late. The failed damper had caused poor air flow which led the evaporator coil icing up and the compressor overheating. It has a high pressure shut off, but R-410a refrigerant acidifies when it is gets extremely hot. This seems like a flaw given the nature of refrigeration, we’re manipulating the temperature using ambient air and fans after superheating the refrigerant so that it subcools when it evaporates. While I am a fan of improving the impact we have on the environment, many times there are unintended consequences that are missed by not having a wide view of the issue. A failed HVAC system requires repair and replacement, which is also not great for the environment. Also, such damage can lead to refrigerant leaks. R-410a is better than R-22 with respect to ozone depletion, but it still isn’t perfect.

The AC had failed, again; the acidification damages the interal components of the compressor which leads to debris clogging the expansion valve. However, I was prepared. I knew what I wanted to replace the system with and I knew I didn’t need a new furnace or anything else. I decided to buy a heat pump system to replace the AC and hopefully reduce or eliminate my need for natural gas to heat my home. I also wanted to eliminate the zoning board and dampers from the zoning and have entirely independent zones… scaling out.

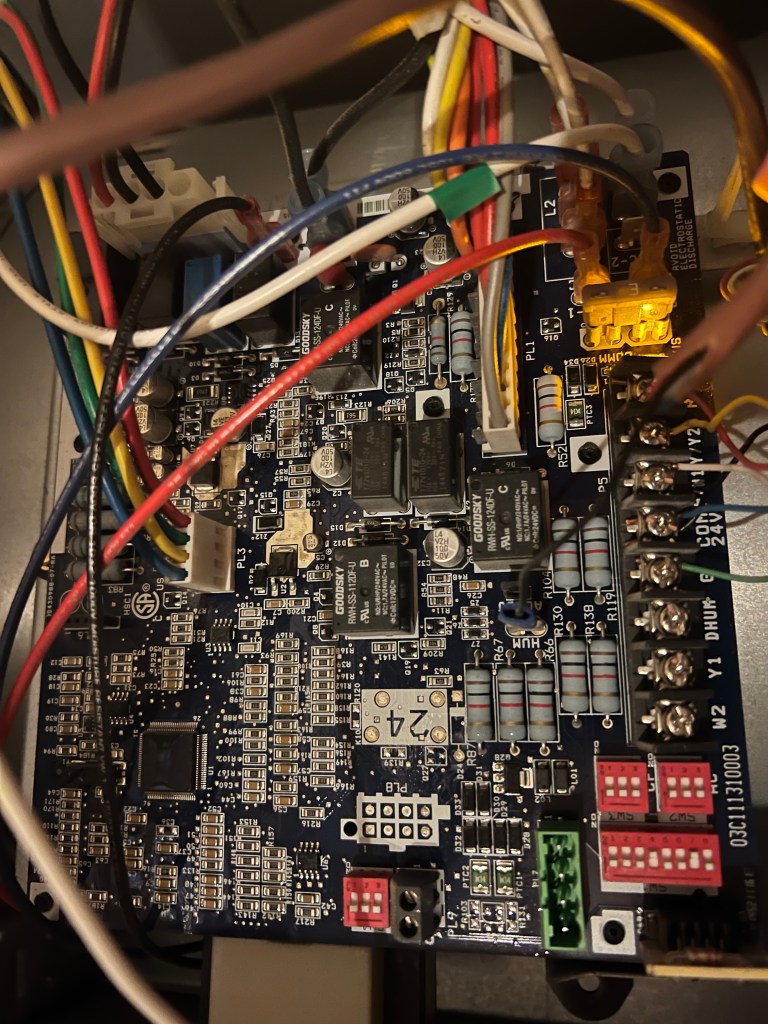

So, I ordered the new heat pump and evaporator coil. I poured a new pad for the heat pump condenser to sit on (400 lbs. of concrete). I installed the new system and it worked out fantastically… except I had rigged some things up in my impatience. Because the zoning system caused the failure I wasn’t exactly comfortable with relying on it. I used the downstairs thermostat to control the heat pump and the upstairs thermostat to run the fan. There was something I wasn’t comfortable with wiring. How could I get the existing furnace and its control board to work in a dual-fuel way?

The Analogy

In my learning, I understoof the several wires involved in running the system. I had replaced my zoning board because some of the resistors and capacitors had rust on them. Here was my understanding of the wiring:

- W = Heat

- Y = Cooling

- G = Fan

- O/B = Reversing Value (only for a heat pumps)

This model in my mind worked well for understanding ther previous system. I bought new Ecobee thermostats and wired them up prior to the system failing. It wasn’t the first time I had installed thermostats and the model came from this understanding.

The thing I couldn’t wrap my mind around was how, with this limited set of wires, does a single W wire control the heat for both the heat pump and the furnace when they can’t run at the same time? It is just on or off, energized or not energized, voltage or no voltage.

The Failure

First Principles Thinking is a hallmark of physics and reason. This would have served me well in this case, but I was relying on the model in my mind. Some combination of the fan wire and the reversing valve could surely make this work, but is that what really happens?

Short answer, no.

The analogy was the failure. In reality, it is super simple when you look at the electronics. Here is what the wire really meant:

- W = Furnace

- Y = AC/Heat Pump

- G = Fan (when not controlled by furnace)

- O/B = Reversing Valve

This is a distinct difference. The model in my mind had me wondering how the single W wire could send a signal that could run either the heat pump or the furnace, but only one at a time, because I associated W with heat. The W wire doesn’t even run to the condenser unit when you look at the first diagram!

W did in fact not mean heat. It meant furnace. Y was used to control the heat pump whether it was cooling or heating; the control for heating or cooling is controlled by the O/B wire that runs the reversing valve. Do not mind the wire colors here, the white wire is connected to D; the communication wire I purchased from Home Depot only had 5 wires, so white is connected to D (which is not being used currently, but it would be for a heat strip to defrost the heat pump in the winter, as needed) and green is connected to B (this is the same as O/B and operates the reversing valve, which is what makes a heat pump different from an air conditioner… the reversing valve allows it to work backwards, shunting heat from the frigid outdoors to the inside, rather than shunting heat from indoors to the hot outside). Also, don’t mind that the communications wire is next to the high voltage power lines, I moved those.

Understanding the fundamental reality of how things are working is significantly more valuable than having a vague understanding based on analogy. This still doesn’t mean I am an expert at this, I am sure there is much more to learn.

The Lesson

Learn how things actually work. It is worth knowing and it is valuable. Guessing or having a vague idea doesn’t serve you well when things get more antiquated. This wasn’t my first lesson in this during this very week. Some of the lessons were more IT centric, but the lesson serves us well regardless of the discipline.

Also, learning is valuable, period. Learning new things is valuable on its own. It helps you exercise your skills for learning. It also provides you value in navigating the world. Ultimately, it creates a sense of self-worth. You’re a capable person that can learn.

On another note, I do plan to eliminate the zoning board and the dampers. Whenever we build a solution it becomes less reliable as we add components to the stack in a north/south manner. The zoning board is a point of failure and the dampers are a point of failure. Not only do their failures mean the system doesn’t work, the failure can damage other components. The plan is to add a second heat pump with another evaporator coil and air handler for the upstairs and completely separate the return and supply air ducts. This is an expensive solution, but it will make the system more reliable by scaling out and eliminating some of the north/south components. In addition, the system will run more efficiently. The old AC operated at 13 SEER (which was a shock to me as I bought a high efficiency system; have to stay on top of those home builders and installers). The new heat pump is only more efficient at cooling because it runs at 17 SEER when in 3-ton mode. When I add a second heat pump, I will be able to switch them each to 2-ton mode which will mean that they operate at 20 SEER. Also, if one system fails, the other will still be operating. HVAC really needs some disruption.